Krebs & Riedel Schleifscheibenfabrik GmbH & Co. KG

Booth number: AC 3-9

www.krebs-riedel.de

About us

KREBS & RIEDEL - Innovative grinding technology since 1895

The cornerstone of the Krebs & Riedel grinding wheel factory in Bad Karlshafen was laid some 125 years ago. Today the family owned company operates worldwide as a manufacturer of individually manufactured precision grinding wheels and impresses with innovation and solution-oriented application technology advice. Above all, customers from the automotive, aerospace, mechanical engineering, medical technology and wind power sectors rely upon the high-precision products manufactured by Krebs & Riedel. In addition to conventional grinding wheels, cutting wheels, cup grinding wheels and grinding segments with ceramic and synthetic resin bonds, Krebs & Riedel also manufactures CBN and diamond tools with ceramic bonds, as well as honing rings. The medium-sized family business with over 250 committed employees has an annual turnover of 31 million euros. Krebs & Riedel is one of the global innovation leaders in abrasives and has subsidiaries in China and India and a strong distribution network in more than 30 countries worldwide.

Address

Bremer Straße 44

34385 Bad Karlshafen

Germany

E-mail: mail@krebs-riedel.de

Phone: 056721840

Internet: www.krebs-riedel.de

No. 111 South Yu Tian Rd., Rm. 502-1, Anting, Jiading District

201805 Shanghai

E-mail: sales@krebs-riedel.cn.com

Phone: +86 21 59950913

Internet: www.krebs-riedel.cn.com

No. 174/F, 2nd Main, 60 Feet Road, AECS Layout “B‘ Block Singasandra, Hosur Road

Karnataka

560068 Bangalore

India

E-mail: sales@krebs-riedel.in

Phone: +918495926527

Internet: www.krebs-riedel.com/

Contact person:

Frank-Michael Dresbach

Sales Manager Asia / Senior Application Engineer

E-mail: dresbach@krebs-riedel.de

Phone: +4915117424363

Products & Services

KREBS & RIEDEL - Innovative grinding technology since 1895

Today the family owned company operates worldwide as a manufacturer of individually manufactured precision grinding wheels and impresses with innovation and solution-oriented application technology advice. Above all, customers from the automotive, aerospace, mechanical engineering, medical technology and wind power sectors rely upon the high-precision products manufactured by Krebs & Riedel. In addition to conventional grinding wheels, cutting wheels, cup grinding wheels and grinding segments with ceramic and synthetic resin bonds, Krebs & Riedel also manufactures CBN and diamond tools with ceramic bonds, as well as honing rings. The medium-sized family business with over 250 committed employees has an annual turnover of 31 million euros. Krebs & Riedel is one of the global innovation leaders in abrasives and has subsidiaries in China and India and a strong distribution network in more than 30 countries worldwide.

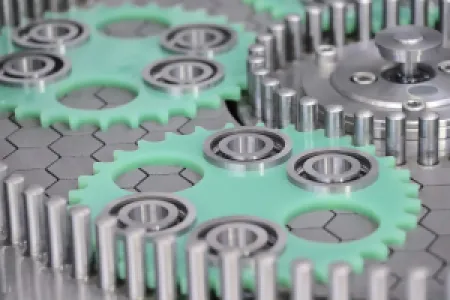

Gear grinding wheels

Krebs & Riedel is specialized in gear grinding. Gears are among the most important mechanical elements in the construction of transmissions, vehicles and machinery. Gear grinding is one of the most important methods for meeting these high demands. For this purpose, Krebs & Riedel provides proven grinding tools for virtually all types of machines when it comes to continuous generative grinding, profile grinding, gearshafts and bevel gear grinding.

Conventional grinding wheels - Vitrified bond (V)

A major advantage of vitrified bonding is the controllable porosity. Highly porous grinding wheels are in particularl needed for productive deep and creep-feed grinding processes to transport the cutting fluid directly into the contact zone and to optimally remove the generated grinding chips and heat.

Superabrasives: CBN and diamond tools, the toughest abrasive in the world

Top high-precision grinding of hard iron and steel alloys or hard and brittle materials, the best removal rates and the longest service life are still provided by the hardest materials in the world: CBN and diamond. Cubic boron nitride, CBN for short, is particularly suited to difficult to machine or high-alloyed hardened steels with a hardness of 54 HRC or more such as high-speed steel, tool or chrome steel, nickel-based alloys, powder metallurgy steels or white cast iron.

High performance DIA & CBN double disc grinding wheels for face and finegrinding

High performance DIA & CBN double disc grinding wheels for face and finegrinding Krebs & Riedel has many years of experience and references in double disc grinding. We offer tailor-made solutions for a wide range of applications, machines and workpieces in the area of face and finegrinding. Krebs & Riedel manufactures double disc grinding wheels up to 1500 mm outer diameter made of DIA and CBN in vitrified bond for the effective creation of flat surfaces with a high surface quality and shape tolerance for a wide range of different materials. The range includes grinding tools in different segmentation for single and double disc grinding machines with and without planetary kinematics. Compared to other systems, the vitrified bond system by Krebs & Riedel allows the production of very free cutting and porous coating structures. This results in a significant increase in productivity.

Cut-off wheels and rough grinding wheels in resinoid bond

The resinoid bond is a bond type well tailored to the grinding task. In resinoid bonds, resins are used as binders, into which fillers are mixed in addition to the abrasive grains. Resinoid-bonded grinding wheels are characterised by having a good cutting performance and cool grinding. Compared with vitrified bonds, resinoid bonds are known as soft, fast and cool grinding bonds. They have a very wide range of applications. Depending upon the application, the bonds can be used for either dry or wet grinding. Based on the production methods and the low curing temperatures, grinding tools with resinoid bond are usually the least expensive among the different bond systems. Due to the low curing temperature, they can easily be used for all types of abrasives.